Amplifier Heatsink

An amplifier heatsink, also called "heatsink", is a mass of aluminium, which draws away the heat from the bipolar junction transistors attached to it. Power transistors usually heat up, and without this thermal management, they would readily fail. I have seen three types of thermal management systems used in amplifiers. The simplest one is the passive cooling technique, which employs a very large heatsink with fins. These are usually expensive due to the large mass of aluminium that is required.

Cheaper cooling techniques involve a very small heatsink with a cooling fan attached to increase its effectiveness. Usually, the cooling fan remains powered all the time. Techniques that are slightly more expensive involve cooling fans controlled by a temperature sensor. In this design, the fan receives power for short durations keeping the temperature to a constant value.

Alto PBM8 500 MK2 Cooling Fan

The thermal management on this amplifier is very simple and cost effective consisting of an aluminium block with a cooling fan. The fan is the same type usually found in computer enclosures. This fan does not have an rpm sensor, and therefore if it blocks up or fails, then the amplifier may overheat. Hence, it is a good idea to ensure that it is operating properly.

Removing Thermal Paste

Ideally, you want to remove the old thermal paste from all the transistors. When doing this, remove the mica layers that are usually between the transistors and the heatsink. Usually the mica layers are disposed of and new layers used; however, it is also possible to clean them for reuse afterwards if they are in good condition.

Attaching Transistors to Heatsink

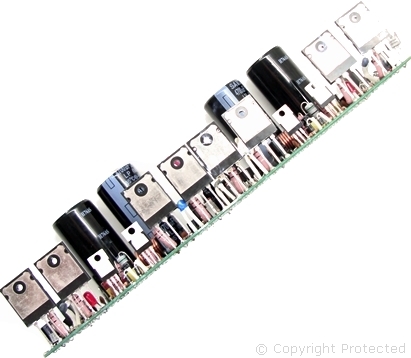

On this amplifier, I fitted a new set of transistors for one channel, and it was ready to be attached to the heatsink block.

Most power amplifiers usually employ mica layers between the transistors and the heatsink, therefore make sure you are using them. The smaller MJE driver transistors must have mica layers as well. If you forget these, then they will short with the metal chassis.

Usually for amplifier power transistors, a non-conducting thermal compound is used and a very thin layer applied to all the surfaces that are in physical contact, including the mica layers. You need this compound to be as thin as possible, as too much will behave as an insulator and reduce performance.

Working in Reverse

Sometimes you have to work in reverse when installing new transistors, because if you solder them to the PCB first and then try to attach them to the heatsink, the screw holes will not align. Hence, temporarily attached the new transistors to the heatsink during their soldering to ensure everything aligns and sits properly.

This Article Continues...

PBM8 500 MKIIPBM8 500 MKII Inside Look

PBM8 500 MKII Diagnostic Logic

PBM8 500 MKII Fault Solved!

Power Resistor

Amplifier Heatsink

Class AB Amplifier

How to Check Transistors

GCA5200T and GCA1943T Transistors

2SC5200 2SA1943 Transistor Replacement

PBM8 500 MKII Diagnostic LEDs

PBM8 500 MKII Power Supply